Because it is not too sharp or too round, a 135-degree angle is popular for woodworking projects. This makes it versatile and can be used in many different ways. If you don’t know how to cut a 135 degree angle on a tablesaw, it can be difficult. But, these simple steps will help you to make it easy!

The most widespread cut for the slanted cuts is the 135-degree angle. This problem can be faced whether you’re making furniture or simply expressing your creativity. It is important to learn how to solve it.

Here are some steps to follow when cutting:

1) First, adjust a miter gauge 45 degrees to align it with the kerf on the blade.

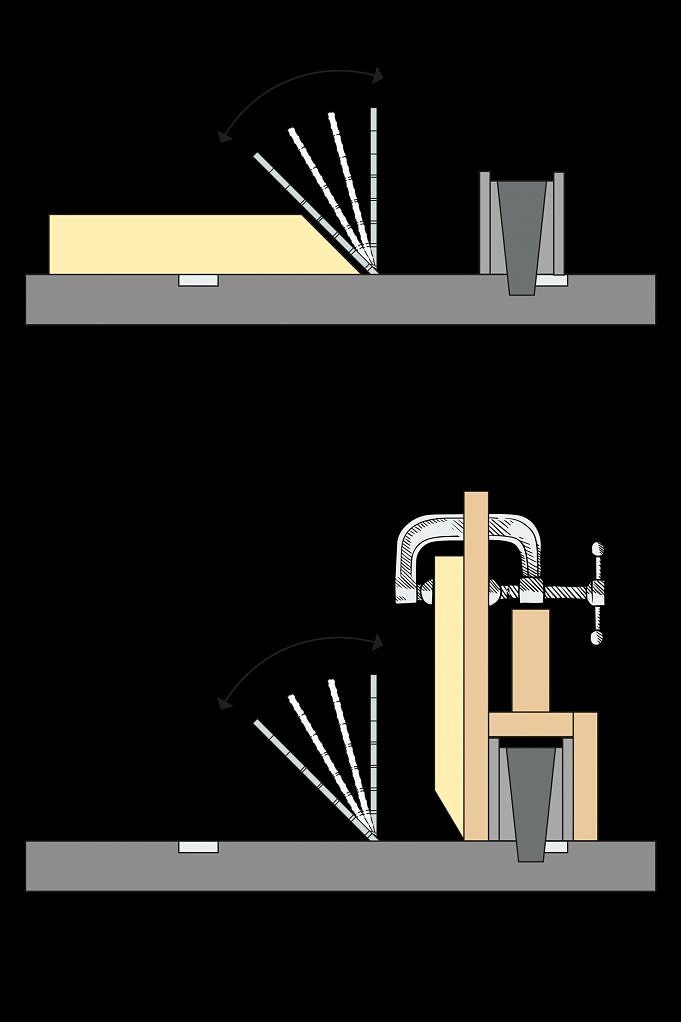

2) Place your scrapboard on the far end the saw table. Slide the miter gauge forward to make the angle. (See image below).

3) After youve made that cut, rotate your scrap piece around and make another 45 cut. Your piece should be able to fit together with a sharp corner if everything went well.

4) Now that you have your 90 cut, you can flip the piece over and make another 45 cut on the opposite end to finish your 135-degree angle

5) Use a brush or vacuum to remove all sawdust from your saw table. You dont want dirt getting in your tool and potentially ruining the blade or causing an accident.

6) Now its time to make the cut! The miter gauge should still be set at 45, and you should line up your piece with the saw blade (preferably in front of the blade). Slide the board into place by placing a clamp on each side. Make sure that your hands arent near when sliding it into place this is when accidents happen!

7) Turn on the saw and slowly push forward to start cutting. Keep a close eye on the angle so you dont accidentally bump it and turn a 90 cut into a rounded edge. If you need to stop mid-cut, make sure to turn off your tool.

8) When youre all done, the last thing to do is remove sawdust from your new 135-degree angle cut! Use a brush or vacuum cleaner and make sure to get rid of any leftover dirt.

Which Blade Should I Use

Ceramic blades are great for this task because they provide a smooth finish and dont kick up sawdust-like other types of blades. Any type of fine-toothed blade can be used if your table saw does not have a ceramic blade.

Safety Rules

- Always wear safety glasses when using power tools.

- When cutting, make sure you are in a well-ventilated area to avoid breathing in sawdust.

- When sliding the blade into place, make sure you have your hands away from it. At all times, keep them behind the miter gauge!

- If you stop halfway through, turn off your tool before doing anything else. Dont attempt to wiggle it free or pull it out theres a risk of injury that way.

- Just wait until it stops moving and then carefully move your hand towards the blade again.

How To Hold The Workpiece?

The workpiece should be clamped securely on the board so that it doesnt move when being cut. You can also use the clamp to prevent any injuries.

How Do I Clean Up The Sawdust?

Before you make any cuts, ensure that you have a dust collection system in place. This will allow the sawdust to be removed safely and efficiently.

If the dust collection system is not powerful enough to remove all the sawdust, you can use a vacuum or brush to collect it.

- To sum it up: how to cut a 135-degree angle on a table saw!

- Make a 45 cut on one end of your piece. Be sure to use a clamp so that you dont lose grip and let go of the wood

- Turn your scrap piece counterclockwise 90 degrees and align it with your blade.

- Open your scrap piece and flip it, lining up with your blade again. This time youll make a 45 cut on the opposite end

- Use a brush or vacuum to remove all sawdust from your table.

- Make sure to line up with your blade before turning on your tool

- Always use safety glasses and be careful with your hands

- Once youre all done, clean up any leftover sawdust

Conclusion

Ive shown you how to cut a 135-degree angle on your table saw. This guide should be easy to follow. Remember to always use caution when working with power tools and please consult your manufacturers guidelines for safety instructions.